Cable welding

high-quality non-ferrous metal compounds in the best qualityWelding non-ferrous metal cables – a challenge in itself

Precision and reliability are important criteria for cable connections in motor vehicles, in medical technology, in electronics and in many other industries. The perfect electrical conductivity must be guaranteed as well as the long-term durability of the connections.

Copper – a special material with special properties

The most common conductor material for cables is copper. The non-ferrous metal can be welded just as well as steel materials, taking into account its chemical properties. However, its significantly higher thermal conductivity means that a large part of the welding energy introduced flows into the surrounding material and is no longer available for melting. In order to maintain the melt flow, a concentrated application of heat or preheating of the component is required.

Another problem with welding copper is that when it is very hot it tends to absorb gases from the air. These, combined with expanding when heated and contracting when cooled, can result in an inferior welded joint. To prevent this, a welding process is required that is optimally tailored to the requirements of the non-ferrous metal in terms of welding current, welding time and electrode force.

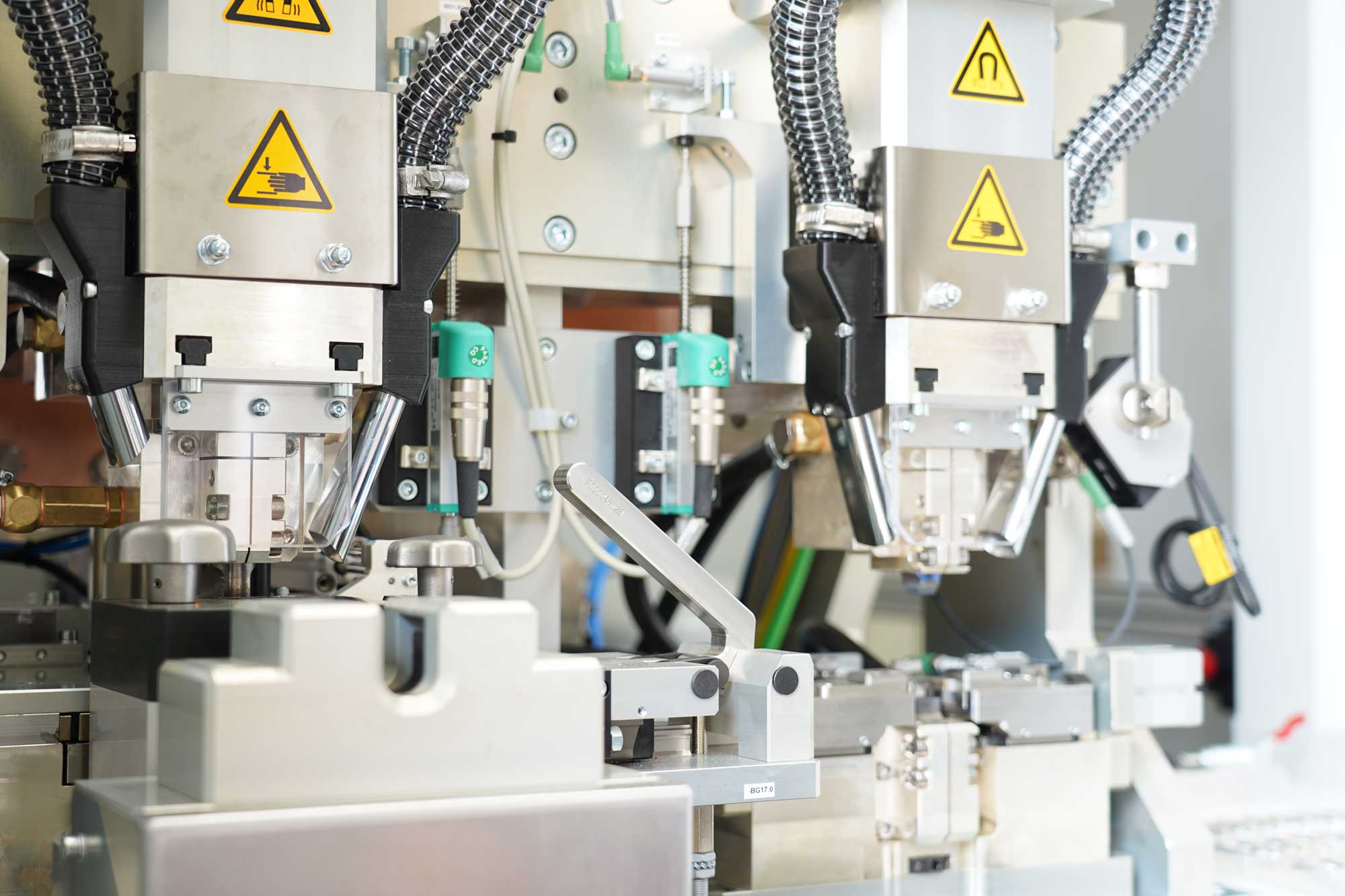

Professional cable welding – high-quality connections with machines from Strunk

Strunk Connect supplies tailor-made solutions for cable welding, in particular for connecting copper and other non-ferrous metals within cable sets for series with cable cross-sections from 0.13 to 120 square millimeters. Mixed connections can also be processed without any problems. For example, compounds of copper, brass, nickel, zinc or silver are possible. Our systems are just as suitable for use in pre-assembly as they are as a mobile variant on the cable board, as independent, partially or fully automated systems or as modules for integration in cable processing centers.

Special series are equipped with a so-called sequencer functionality. This enables the electrodes to be continuously adjusted to different successive processing cross-sections – completely automatically and without operator intervention. The sequences can be transmitted via barcode, via the HOST control system or via a higher-level SPS within a machine. Using the transmitted sequences, we map the cable set including all welding nodes in our special control systems.

All systems developed and manufactured by us have monitoring strategies designed for the automotive industry and medical technology, which guarantee reproducible welds of the highest precision and quality. According to the requirements of the OEMs, the data of each welding process is tracked and saved in a database.

Would you like to find out more about our solutions for cable welding? Just get in touch with us . We are happy to answer all of your questions.