Compaction

Optimal preparation for joining and plugging processesCompacting – compressing cable ends or strands to exact final dimensions

The term compacting refers to the compaction of cable or strand ends by resistance welding. This allows for precise geometries with high surface quality to be achieved without burrs and fraying. Due to the gap-free nature of our tool technology, you can compact even fine strips almost burr-free.

Cable welding processes with high welding force and reinforced tool technology are used for compaction. Thus, you can achieve the final dimensions within the shortest possible welding times and minimize the heat input.

Compacting can precede a subsequent welding process. However, it is also suitable for preventing wire ends from splicing or for replacing the ferrule. This means that the compacted cable can be installed in a housing, for example.

Compacting to prepare for connection processes

A subsequent welding task can potentially be simplified by pre-compacting. In the case of automation, monitoring must also be ensured for the additional pre-compacting process.

Compacted cable or strand ends can be assembled, overlap or butt welded. A cutting, punching or calibrating unit can be attached to the machines as required to achieve the most precise final dimensions and surface quality after compaction. Even round calibration is technically feasible. Compacted surfaces can also be processed in such a way that a hole can be created in the compacted surface using a punching calibration unit.

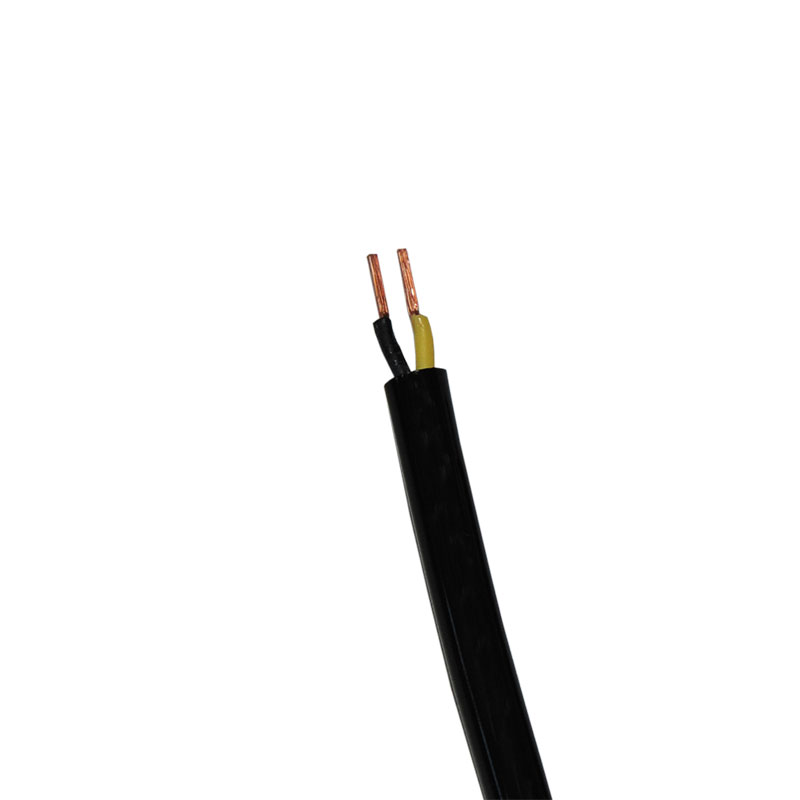

Compacting can be used for single strands and twin cables as well as for twisted pair wires and multiple-sheathed cables. All of these can be processed by manual workstations, semi-automatic machines with a subsequent cutting and calibration station as well as fully automatic systems with subsequent welding and assembly processes. Insulated conductors or continuous braided strands are suitable as starting material. They can be fully automatically compacted inline in variable lengths and types using our automatic stranding machines.

Process-reliable welded connections for automotive electrical systems

In order to enable the production of different consecutive cross-sections without costly set-up times and downtimes, we also offer modules with sequencer functionality. Additionally, our range includes specialized modules for linear transfer systems with lifting tools.

Our modules with individual tools feature electrode and ceramic cassettes for quick changeover, which enable rapid conversion to another application.

Machines

(customer-specific solutions as an example)

KM15 for compacting cable ends

This KM15 system is available as a module and for table integration. It features a front cable feed incl. guarding and foot switch and is suitable for smaller cable cross-sections. The machine can be equipped with a M4Ts control system or MCD PC/2 controls incl. database.

Compacting module KM CFK for use on wire processing centers

This KM CFK compacting module is designed for producing end and feed-through connectors between bare and/or tin-plated copper strands from 0.34 to 6 mm² in cross-section. It is suitable for direct use on wire processing cable centers and can be set up as a swivel arm or transfer machine.

Thanks to its solid plate construction with integrated transformer, the secondary paths can be kept optimally short. Furthermore, all necessary mechanical and electronic precision elements are located inside the machine body.

The tool is mounted on a console, centered and secured by clamping cylinders. It consists of a base plate, a head plate and a movable upper electrode holder. The latter is in turn supported by backlash-free and maintenance-free column guides.

The current generation of tools includes quick-change cassettes for the upper and lower electrodes as well as for the side ceramics. This means that the respective application can be changed over as quickly as possible within the designed cross-section range. Long set-ups or adjustment work can thus be avoided.

Technical specifications:

| Range of application: | 0.34 mm to 6 mm² (depending on strand type and desired combination of strands) |

| Machine type: | module for use on a wire processing center |

| Feeding: | automatically via the wire processing center |

| Welding control: | M4Ts or MCD PC/2 |

Fully automatic braiding machine for compacting continuous braids

This fully automatic welding system with integrated pull-punch unit is suitable for variable lengths and cross-sections up to 40 mm². It is also available for the HV range (up to 120 mm²) and for compacting large areas (see HV module connectors).

Semi-automatic processing system for twisted pair airbag wires and sheathed cables

This is a transfer chain system with manual strand feed incl. stripping of the twisted pair wires and zero cut, a double compacting unit, zero cut compacting as well as OK and NOK selection. It delivers precise dimensions for subsequent welding processes.

Samples

Automatically compacted braids, single or multiple feed

Suitable for strands with cross-sections between 0.35 mm² and 120 mm² as well as large compaction areas